In the high-end field, in addition to the material of plastic itself to meet the requirements of laser cutting processing, but also to solve the problem of laser lettering processing, but also to solve the problem of how to achieve precision, clean, fast and efficient in the process of welding, cutting, carving, drilling and so on.

Now the latest plastic processing can be processed by laser cutting machine. laser engraving machine focuses the laser beam on the surface of plastic material, melts the material with high temperature characteristics of laser, and makes the laser beam and plastic products run along a certain track, so that the ideal plastic products can be obtained.

When it comes to plastic products, many people think of buckets, baskets, basins, etc. sold at roadside stalls. With the development of science and technology, plastic products are not only used in the above products, but also in automobiles, electronics, medical devices, and even in aerospace high-tech, precision, and cutting-edge fields. But to apply in these high-end fields, in addition to the material of plastic itself to meet the requirements of laser cutting processing, but also to solve the problem of laser lettering processing, but also to solve the problem of how to achieve precision, clean, fast and efficient in the process of welding, cutting, carving, drilling and so on. Laser cutting machine processing plastics has the following advantages:

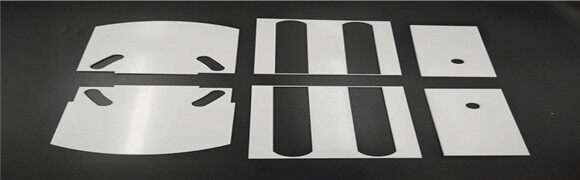

First, the quality of the plastic nozzle of the laser cutting machine is good. It belongs to non-contact cutting. The cutting edge has little thermal effect, and there is basically no thermal deformation of the workpiece. It completely avoids the collapse of the edge formed during the die blanking. The laser cutting seam is smooth and flat, and generally does not need secondary processing.

Second, laser cutting machine processing of plastic materials can improve the speed of new product development: after the product drawing is formed, laser processing can be carried out immediately, and samples of new plastic products can be obtained in the shortest production cycle.

Thirdly, laser cutting machine cutting plastic materials can save the cost of plastic mold, plastic laser cutting processing does not need mold, no mold consumption, no need to repair the mold, save the time to replace the mold, thus saving processing costs, reducing the cost of manufacturing, suitable for large or small batch of plastic products processing.

Plastic is widely used in home appliances, automobiles, mobile phones, PCs, medical devices and lighting appliances, so the processing and application of plastic is also essential.

It is also a tissue box, and this tissue box processed by laser cutting technology has better transparency, such as crystal, which is very suitable for home, hotel, office, etc., and can also use laser carving technology to carve personality logo.

The best choice is to use laser engraving machine to carve advertising crystal. The above two characters are carved and formed once by laser engraving machine, without additional polishing and polishing, and it is very flexible. Laser cutting machine is used in plastic material cutting and processing. When processing plastics, the traditional machining method is to directly affect the drill bit and other machinery on plastic work pieces, which causes plastic deformation uniformly, and also forms rough edges in the processing area. In order to meet the production requirements, it needs to be processed, and the processing speed will be slow and the precision can not meet the requirements. But the laser cutting can avoid the above disadvantages, greatly accelerate the research and development of new plastic products, and accelerate the application of plastics in high-end fields. With the improvement of people’s living standard, the market prospect of laser cutting and processing acrylic gift is getting better and better. Laser cutting has been loved by people because of its high speed and simple processing advantages. For example, laser cutting and processing acrylic crafts can be preserved for a long time, without discoloration, without moisture, and can be bright and bright forever.