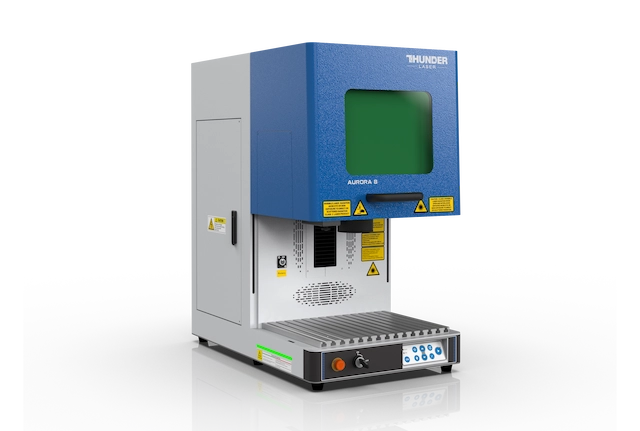

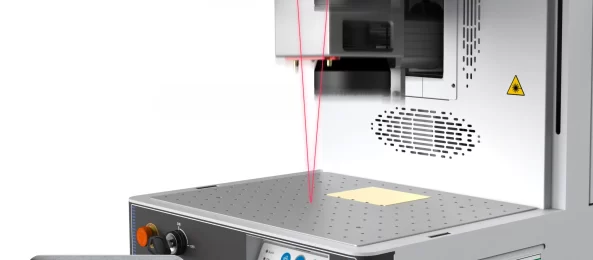

Optical fiber laser engraving machine with fully enclosed cover can be used for marking metal and non-metal materials. It can mark time, date, text, serial number and part number, company logo, icon, symbol, bar code, 2D code, matrix and vector font on all planar, painting, powder coating, anodizing, electroplating metal surfaces, whether they are flat or curved It's still a cylinder.

Optical fiber laser engraving machine with fully enclosed cover can be used for marking metal and non-metal materials. It can mark time, date, text, serial number and part number, company logo, icon, symbol, bar code, 2D code, matrix and vector font on all planar, painting, powder coating, anodizing, electroplating metal surfaces, whether they are flat or curved It's still a cylinder.

What is special about a MOPA laser is that its pulse duration is variable: Long or short pulses can be adjusted in steps between 2 and 500 ns(60w). Additionally, the laser parameters pulse duration, pulse frequency and pulse energy can be adjusted nearly independently of one another what results in high flexibility.

The dynamic magnetic structure of the galvanometer motor provides excellent stability, high positioning accuracy, fast marking speed and strong anti-interference ability. With an engraving speed of 8000mm/s, this machine outperforms competitors.

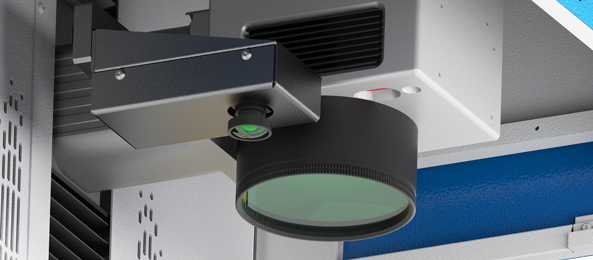

The Aurora 2.0 features geometric optics to achieve fast and precise focusing ability automatically. This innovative feature works by firing out a short laser burst, which then travels back towards the sensor, where the software calculates the time it takes for the light to leave and return, resulting in a very accurate measurement of how far away the object is.

Simply press the button and wait for the two red dots to merge into one. Once they have combined, the focus is completed.

Adjust the manual focus tool until it just makes contact with the object to be marked. The foucs is achieved.

Eye safety is important when working with any type of laser. Our design includes tempered glass viewing windows to ensure you are protected from light as well as odors from your materials.

| STANDARD SPECS | |||||||

| Fiber system | AURORA 8 | AURORA 8 PRO | AURORA Lite | ||||

| Marking area | 4.3″×4.3″/110×110mm | 5.9″×5.9″/150×150mm | 5.9″×5.9″/150×150mm | ||||

| Max work Height | 7.9″/200mm | 5.7″/145mm | 7.9″/200mm | ||||

| Max marking speed | 2m/sec, 200cps | 8m/sec, 800cps | 7000mm/sec, 700cps | ||||

| Z-axis | Motorized Z-axis, 15.4″/390mm | Motorized Z-axis, 16.9″/430mm | |||||

| Table | Alumina table, 14.2″×10.5″/360×265mm | Alumina table, 14.7″×11.3″/375×288mm | |||||

| Net weight | 71kgs/157bs | 72kgs/159lbs | 72.5kgs/159.8lbs | ||||

| Housing dimensions(W*D*H) | 27.7″×17″×32″/703mm×430mm×812mm | 16.9″×29.7″×31.4″/430*755*799mm | |||||

| Frequency | 20W 20-60kHz | 50W 50-100kHz | 20W(MOPA) 1-4000kHz | 50W 50-100kHz | |||

| Pulse width | 110ns | 2-350ns | / | ||||

| Cooling | Air cooled | ||||||

| Red dot pointer | Laser Power<1mW, 630-680nm | ||||||

| Software | EzCad2 | EzCad3 | EzCad2/Lightburn | ||||

| Optional F-theta lenses | 5.9″×5.9″/150×150mm | 7.9″×7.9″/200×200mm | 4.3″×4.3″/110×110mm | 7.9″×7.9″/200×200mm | 4.3″×4.3″/110×110mm | 7.9″×7.9″/200×200mm | |

| Materials | apply |

| Metallic materials | √ |

| Rigid plastics | √ |

| Hardware tools | √ |

| Industrial accessories | √ |

| Stainless steel | √ |

| Carbon steel | √ |

| Aluminium | √ |

| Iron | √ |

| Steel | √ |

Our Fiber Laser Marking Machines can engrave a wide range of materials: Metals,Plastics,Leather

Transformative! After a year of struggle with a hobby laser, tonight marks a successful shift to a fiber laser’s amazing capabilities.

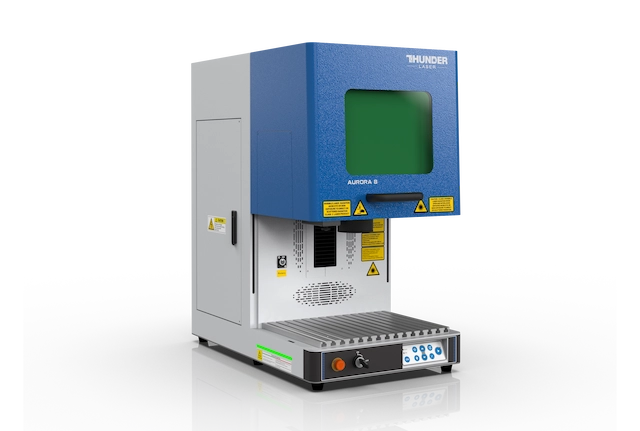

I have had my Thunder Laser Aurora 8 50 watt for a year now and so far, the customer service has been amazing, my machine makes perfect cuts every single time and it is extremely fast too

The Thunder Laser team was incredibly kind and helpful when I needed to replace a part of my fiber laser machine. Their responsiveness, efficiency, and friendliness were outstanding! Thanks!

Thunder Laser is by far the best!!! I have had my Aurora 8 for about 7 months, and each day I am amazed by the quality of output and performance. It is truly a wonderful machine for an unbeatable price point!!!

I utilize three Thunder Laser machines at our local Maker space, and I love them! These fiber lasers endure constant use and are holding up very well. I came for the woods lab but I’m staying for the precision of these fiber laser machines!

Could not recommend Thunder Laser’s enough.Not only is the machine reasonably priced and well built but the service that Glenn offered was nothing less than amazing. Cheers guys.

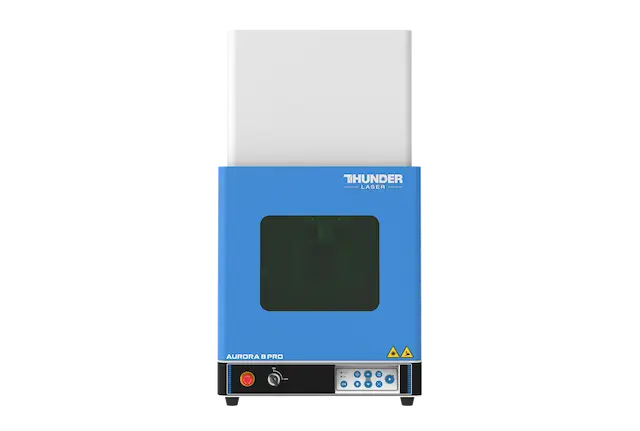

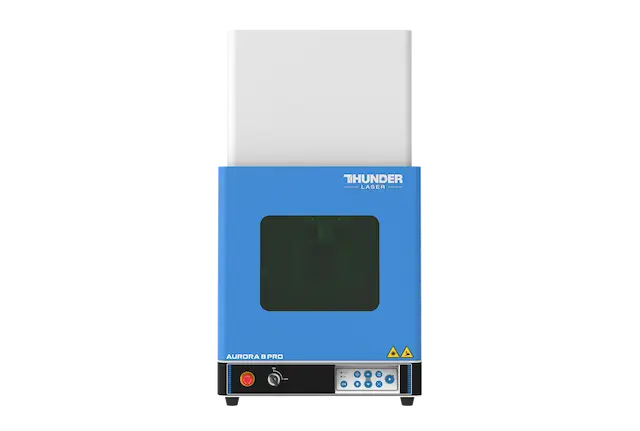

Speed: Both the Aurora Lite and Aurora 8 impress with a maximum speed of 7000mm/s, while the Aurora Pro 8 takes it a step further with a remarkable 10000mm/s, ensuring rapid and efficient performance.

Power and Laser Versatility: The Aurora Lite offers a streamlined 50W fiber laser option, providing a cost-effective solution for various marking needs. On the other hand, the Aurora 8 and Aurora Pro 8 offer a range of power and laser options, including 20W, 50W fiber, or 60W, 100W Mopa fiber, or 5W UV laser, catering to diverse applications and material requirements.

Functionality: While the Aurora Lite boasts user-friendliness and efficient operation at an attractive price point, the Aurora 8 stands out with its autofocus feature, simplifying operation for seamless workflow. With the addition of a camera, the Aurora 8 unlocks its full potential, enabling precise and versatile marking capabilities.Furthermore, the Aurora Pro 8 elevates the experience with its higher marking speed and auto-lift door function, enhancing workflow efficiency and convenience.

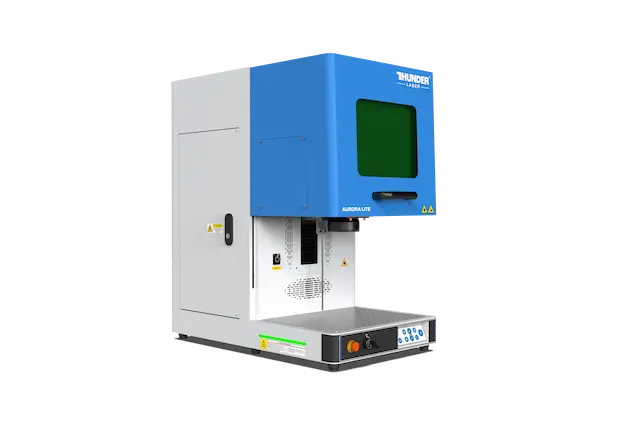

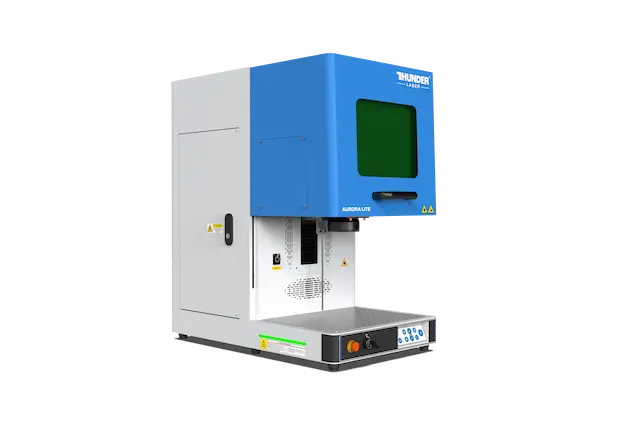

Experience unparalleled affordability without compromising performance with the Aurora Lite, offering exceptional value for those seeking a cost-effective solution for their marking needs.

A lightweight, high-speed fiber laser marking machine that is closer to your expected price and offers stable quality. It can mark on metal materials as well as various other materials like leather and plastic.

Dual red light and manual focusing

No, unlike the Aurora 8, the Aurora Lite does not come with Auto Focus functionality. However, it is equipped with Dual Red Light Manual Focus, along with a focal stick for user convenience.

The Aurora Lite arrives fully equipped with all the essential parts and tools required for seamless setup and operation. This comprehensive package includes the exhaust fan, a convenient tool bag, and even some starter materials to get you started right away.

While the Aurora Lite provides everything you need to get up and running, you may want to consider a stand or table to optimize placement and accessibility. Additionally, a computer is necessary for software installation. For those interested in rotary engravings, we offer an optional rotary attachment to expand your creative possibilities even further.

Setting up our machines is surprisingly straightforward. Typically, we can unbox and set them up in just 30 minutes at a trade show.

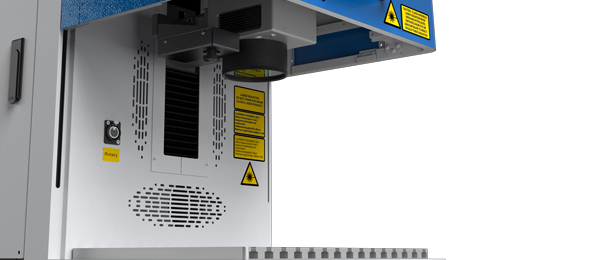

Unlike many lasers that necessitate a complex alignment upon arrival, our machines are robustly constructed to maintain alignment during transit. This design philosophy ensures that if a machine is prone to misalignment during shipping, it’s likely to require frequent realignments, leading to lost time and unnecessary frustration for you.

With our machines, you can expect consistent, hassle-free performance.

Thanks to the stability of the machine. The machine adopts a metal casing, and the heavy metal casing can keep the machine stable even under speed marking, ensuring high quality even at high speeds.

Machine Structure: The Aurora Lite boasts a galvo marking design coupled with a fiber laser source, offering precision and speed in marking applications. On the other hand, the Thunder Bolt features a gantry and belted structure powered by an RF CO2 laser source, catering to cutting and engraving tasks with versatility.

Performance: The distinction in machine structure translates to notable differences in performance metrics. With the Aurora Lite, enjoy an impressive maximum marking and scanning speed of 7000mm/s, ideal for swift and intricate marking tasks. Meanwhile, the Thunder Bolt showcases a maximum engraving speed of 1000mm/s, facilitating efficient cutting and engraving operations.

Material Compatibility: Thanks to their distinct laser sources, each machine excels in different material applications. The Thunder Bolt shines in engraving and cutting a wide array of non-metal materials, offering versatility for diverse projects.

Conversely, the Aurora Lite’s fiber laser source enables it to engrave bare metals with precision, a capability unmatched by the Thunder Bolt.

Synergistic Partnership: Together, the Aurora Lite and Thunder Bolt form a dynamic duo in any workshop setting. Their complementary functionalities enhance productivity and streamline workflows, empowering businesses to achieve greater efficiency and effectiveness in their operations.

Invest in these powerhouse machines to elevate your workshop capabilities and unlock new dimensions of productivity and creativity.

Yes, typically, field lenses with smaller marking areas can produce finer laser spots. Conversely, lenses with larger marking areas can engrave bigger patterns. However, it’s essential to note that larger work area lenses require longer focal distances. Moreover, due to the enclosed housing structure for safety purposes, the maximum work height is consequently reduced.

The standard lens for the Aurora Lite is the F-210, accommodating a maximum work area of 145 x 145 mm. As options, you can select the F160 (110 x 110 mm) or the F290 (200 x 200 mm) lenses as options to suit your specific requirements.

Comes with 50W fiber laser source, Aurora Lite is versatile and can process a wide range of materials, including but not limited to:

1.Metals: Stainless steel, mild steel, aluminum, brass, copper, titanium, etc.

2.Alloys: Various metal alloys including steel alloys, aluminum alloys, etc.

3.Plastics: ABS, PVC, acrylic, polycarbonate, polypropylene, etc.

4.Ceramics: Ceramic tiles, porcelain, etc.

5.Coated Metals: Anodized aluminum, coated steel, etc.

The depth to which a 50W fiber marking machine can engrave depends on several factors, including the material being engraved, the marking speed, and the specific settings of the machine (such as power and frequency). Generally, a 50W fiber laser can achieve engraving depths ranging from micrometers to a few millimeters, depending on the material and the desired level of detail. However, for deep engraving applications, higher-powered lasers or multiple passes may be necessary.

Featuring an ultra-fine 0.024mm focused spot on fiber, experience unparalleled clarity with Aurora Lite’s HD resolution!

Metals, Aluminium, Plastics, Leather, Fiberglass

MOPA fiber lasers can be used to engrave certain materials, especially metals, in a way that produces different colors by adjusting parameters like pulse duration and frequency. This capability is particularly useful for creating color markings on stainless steel, titanium, and other metals. The color variations are a result of interference effects caused by the interaction between the laser beam and the material’s surface, which changes the way light is reflected.

All rights reserved ©2023 Thunder Laser Australia | Sitemap